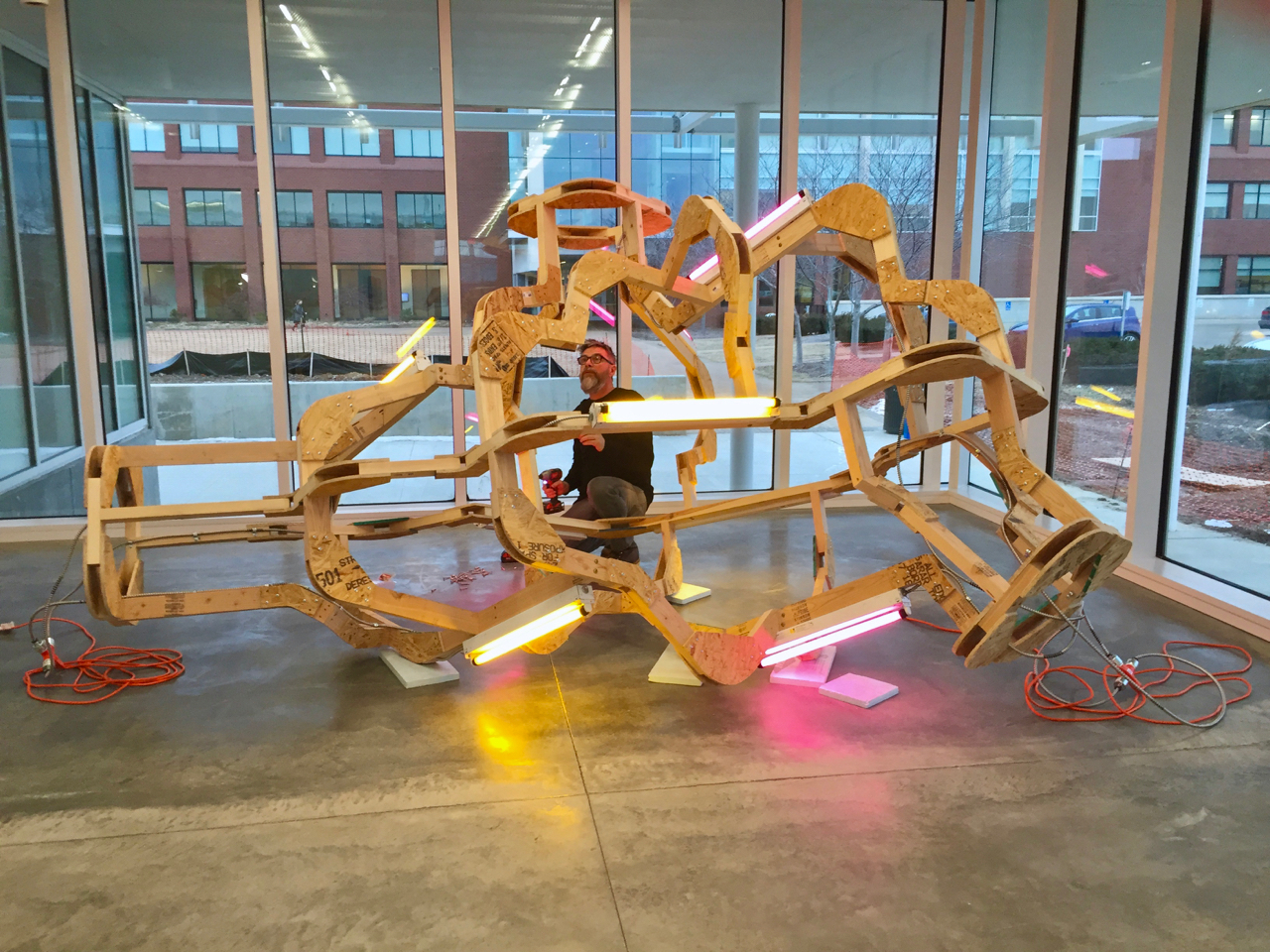

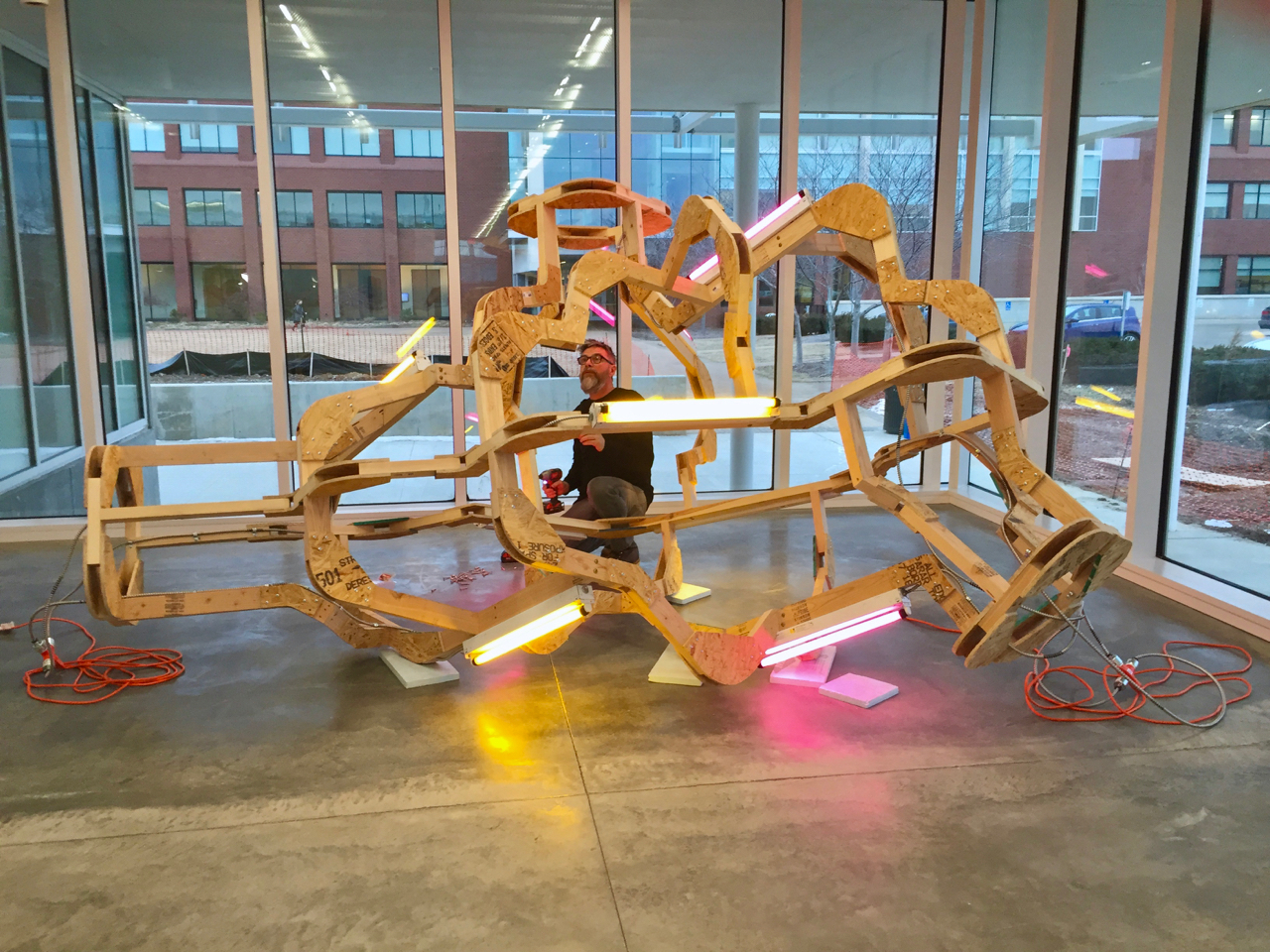

I have to admit, this was a hectic, stressful move. The timeframe, the time of year, and …well…just the TIMING. But it’s slowly coming together. Here’s a small glimpse into the last month of transitioning from ATB to the new FADS building.

I have to admit, this was a hectic, stressful move. The timeframe, the time of year, and …well…just the TIMING. But it’s slowly coming together. Here’s a small glimpse into the last month of transitioning from ATB to the new FADS building.

When Misha Kligman offered up his Painting I and II students to paint bowls for the Empty Bowls event (taking place in Nov., 2017), it was an opportunity that couldn’t be passed up. So Laura Gascogne and some Ceramics students made “blank” bowls and passed the bisqued bowls on to Misha. …and the results were stunning!

Here are some of the individual bowls:

Photo credits: Barbara Sullivan

One of the truly exciting experiences for JCCC students in Sculpture is the casting process.

This intricate, multifold process starts with an idea, which then the student makes a “positive” of using microcrystalline wax. Once made, a wax “sprue” (channel for the metal) is attached. The entire solid piece of wax is then dipped multiple times into a silica slurry, which builds up a “ceramic shell” around the wax. After the shell has dried, it is fired and the wax is steamed/ melted out, leaving a void in which a metal is then poured, such as aluminum or bronze. The shell is then chipped away, leaving the “positive” metal piece, whereby the sprue is removed and the sculpture is cleaned.