Tag Archives: Sculpture

MORE SCULPTURE CASTING

Mark Cowardin’s Bronze Casting Crew

Last week, I posted pics from Angelica Sandoval’s Aluminum Casting. This week, it’s BRONZE in Mark Cowardin’s class on NOVEMBER 10! How do you know it’s bronze?

Bronze is comprised of COPPER and TIN. Tin makes the copper harder, more durable as it was discovered many millenia ago during the Bronze Age. However, it’s the Copper that gives the furnace flame it’s signature green hue.

Angelica Sandoval’s Awesome Sculpture Class Metal CASTING

Casting via the Ceramic Shell process

Photo credits: Barbara Sullivan

One of the truly exciting experiences for JCCC students in Sculpture is the casting process.

This intricate, multifold process starts with an idea, which then the student makes a “positive” of using microcrystalline wax. Once made, a wax “sprue” (channel for the metal) is attached. The entire solid piece of wax is then dipped multiple times into a silica slurry, which builds up a “ceramic shell” around the wax. After the shell has dried, it is fired and the wax is steamed/ melted out, leaving a void in which a metal is then poured, such as aluminum or bronze. The shell is then chipped away, leaving the “positive” metal piece, whereby the sprue is removed and the sculpture is cleaned.

September 2, 2016- IT’S FIRST FRIDAY!!!!

It’s the End of the 2nd Week of the School semester here at JCCC. It’s FIRST FRIDAY. Check out local happenings/ Openings here!

The Students have been busy on their first projects. We have some exciting News to share; JCCC’s Sculpture Program has been featured in the local TV news channel, KSHB 41 Action News. Each year the Sculpture students compete in a chance to get funded to make a sculpture project through JCCC’s Sustainability Program. The chosen students then create a piece out of recycled or renewable material that gets displayed on campus. We are so proud of our Sculpture students. The story showcases the latest exhibit:

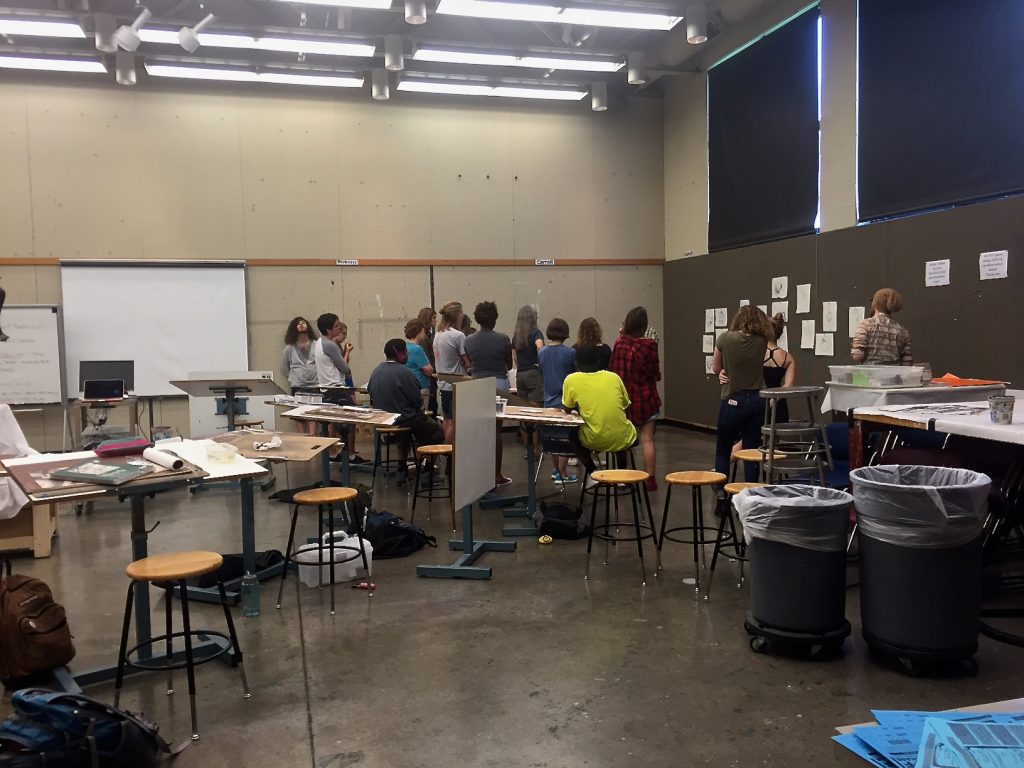

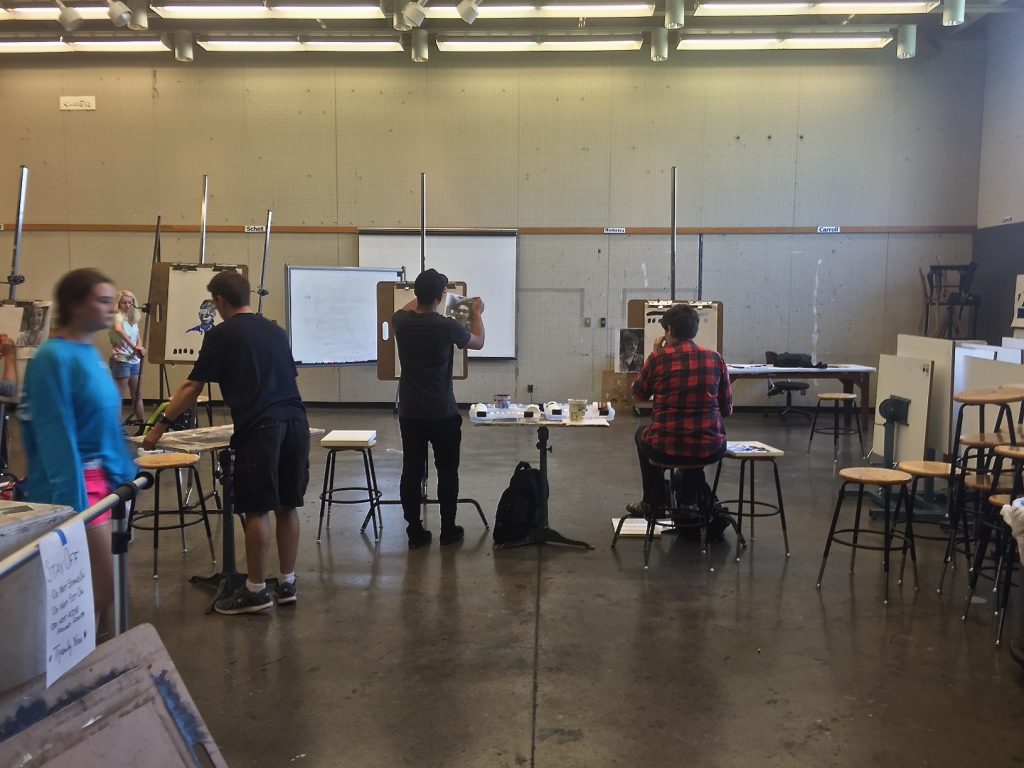

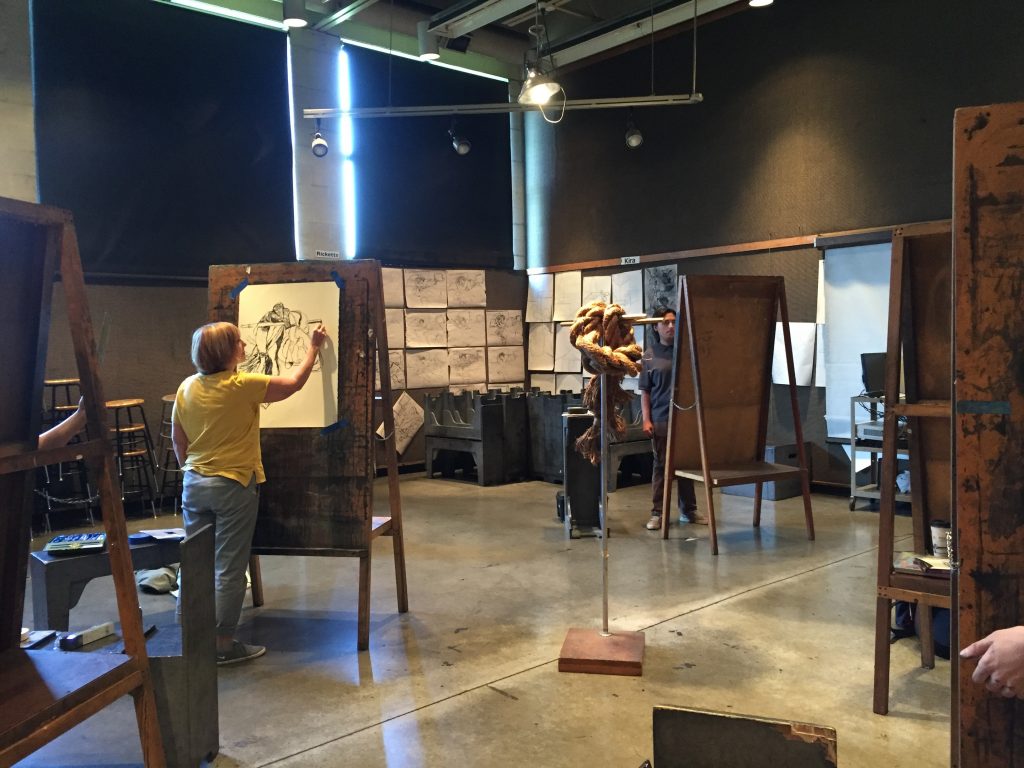

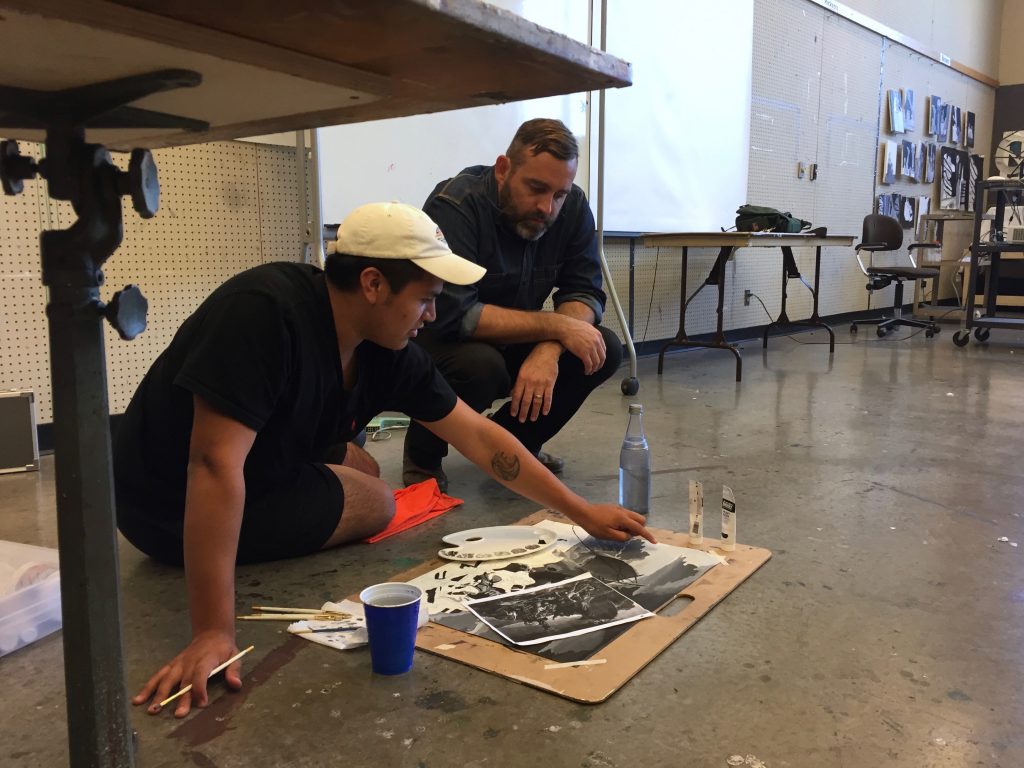

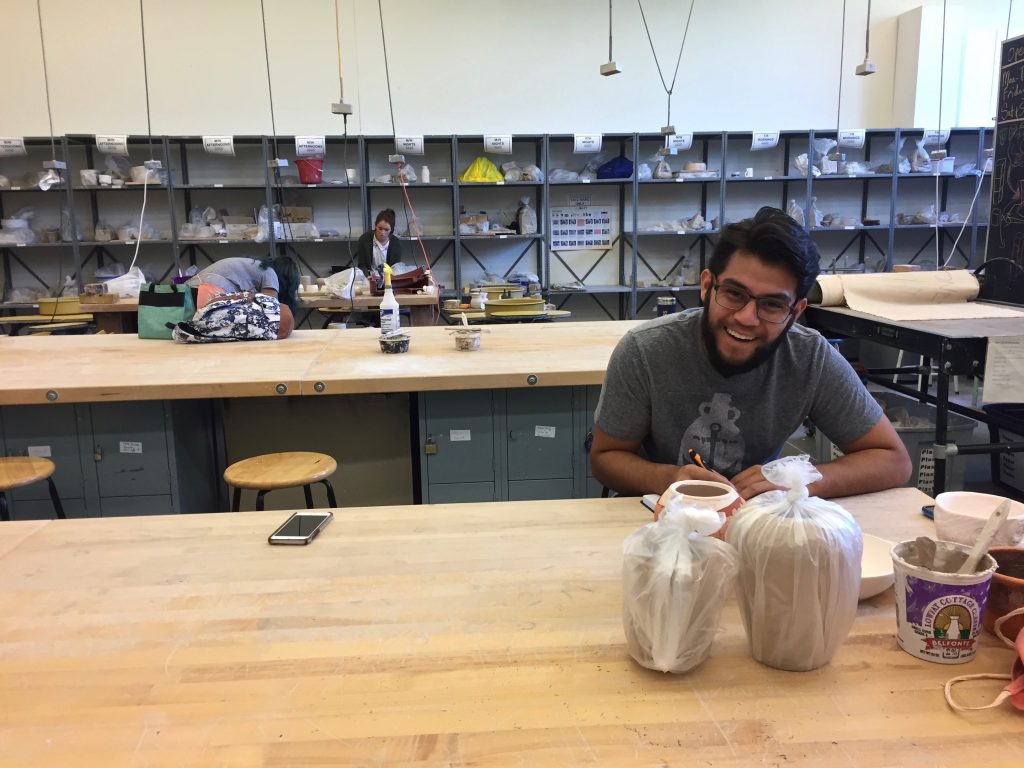

Students eagerly get going on first projects in Fine Arts!